-

By admin

-

October 8, 2025

- 0 Comment

Common Mistakes to Avoid When Designing with Woven Fabrics

Why Woven Fabrics Demand Design Precision

The material you choose isn’t just about looks, it directly impacts how your product performs, how long it lasts, and how customers feel about using it. The Garments industry is evolving as manufacturers adopt new materials, technologies and sustainable practices. Woven fabrics are gracing everything from the clothes we wear to the upholstery in our homes, and are even playing an important role in industries like aerospace, healthcare, and automotive manufacturing. For garment manufacturers and traders, understanding these nuances is vital for maintaining quality standards. At their heart, woven fabrics are products of art, science and engineering, born from the centuries-old intersection of warp and weft threads. They promise structure and longevity, yet they come with drawbacks like stiffness and wear.

Mistake #1: Ignoring the Fabric Grain and Direction

The grain of the fabric is the direction of the threads in a woven fabric, and it significantly affects how the fabric drapes and fits. Beginners often overlook or misinterpret the grainlines on their patterns. In severe cases, if your pattern pieces are not cut on the grain, your fabric will actually stretch and expand as you wear it. Ignoring the grain of fabric can result in loose fabric, mismatched patterns, and weak seams, issues that compromise both style and longevity.

How to avoid:

- Clearly mark the grain lines on your pattern pieces and align them parallel to the fabric selvage.

- Understand fabric behavior and how grain affects drape and fit.

- For stretchy fabrics, align the pattern to take proper advantage of the stretch properties

- Use pattern weights or pins to hold the fabric steady while cutting.

Mistake #2: Choosing the Wrong Weave for Your Garment Type

Not all weaves are created equal, and selecting an inappropriate weave can have a negative impact on both comfort and appearance. For example, heavy twill may work well for durable outerwear, but feel too stiff and restrictive for light, flowing blouses for summer. Similarly, satin weave creates a luxurious, smooth finish but can be slippery and challenging to sew for beginners. Ignoring weaving appropriateness can result in garments becoming uncomfortable, ill-fitting or unattractive. Understanding weave characteristics helps custom clothing manufacturers choose materials that match the intended purpose. Additionally, the texture and appearance of the weave must be consistent with the desired style, as some weaves can enhance or detract from the design of the garment. By carefully matching the weave of the fabric to the type of garment, designers ensure both functionality and aesthetic harmony.

How to Avoid:

- Research the characteristics of different weaves and their suitability for numerous garments.

- Choose lighter weaves for hot climates and heavier ones for cooler climates.

- Create a muslin prototype to assess how the material behaves before committing.

Mistake #3: Skipping Pre-Wash and Shrinkage Tests

Woven fabrics, particularly natural fibers such as cotton, linen, and wool, often shrink during the first wash. This is especially important for garments that require precision, such as tailored shirts, trousers, or fitted dresses. Using proper detergent and washing methods can prevent damage while maintaining the quality of the fabric. Even synthetic blends may benefit from pre-washing to remove excess finishing chemicals or stabilize the fibers. Taking pre-wash changes into account early in the design process saves time, ensures better garment longevity and avoids surprises after manufacturing.

How to Avoid:

- Wash fabric as you ought to take care of the completed garment to account for shrinkage.

- Measure fabric earlier than and after washing to determine shrinkage percent.

- Select detergents suitable for the fabric kind to save you damage.

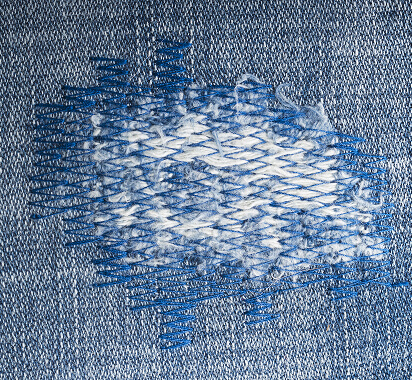

Mistake #4: Using Incorrect Stitch Types or Thread Tension

Incorrect stitch type or improper thread tension can seriously affect a woven garment, causing stitches to shrink, tear, or unravel. Unlike knitted fabrics, woven materials generally lack stretch, making precise stitch selection important for durability and appearance. Different weaves may also respond differently to stitching, so paying attention to the type of thread whether it is a cotton, polyester, or blend can affect the strength of the seam. Ignoring these details can make even high quality clothing appear poorly made. By fine-tuning the stitches and tension, designers achieve clean, professional seams that enhance both fit and longevity.

How to Avoid:

- Use straight stitches for seams and zigzag stitches for completing edges.

- Fine-tune your sewing machine’s tension settings to fit the cloth weight.

- Always take a look at stitch settings on fabric scraps before sewing the actual garment.

Mistake #5: Overlooking Ease and Fit Adjustments

Designers must consider shoulder, bust, waist and hip measurements individually, as woven clothing does not compensate for fit errors. Ignoring these adjustments can also affect the longevity of the garment, as tight stitching can strain and tear over time. Patterns that anticipate stretch can lead to misaligned hems, uneven gathering, or awkward drape. Proper planning and test fitting ensures that the clothes remain comfortable, functional and visually appealing.

How to avoid:

- Include additional seam allowances to accommodate fit adjustments.

- Add darts or pleats to give the garment body shape.

- Make a muslin version of the garment to test the fit before cutting into the final fabric.

Mistake #6: Neglecting Proper Seam Finishing

Woven fabrics are highly prone to tearing, which can compromise the durability and professional look of the garments. Ignoring seam finishing techniques can cause threads to unravel, seams to weaken, or edges to appear incomplete. Additionally, poorly finished seams may warp after repeated washing, reducing the lifespan of the garment. Investing time in proper finishing ensures a professional, polished product that maintains its structure and quality over time. Designers should also consider decorative finishes such as topstitching, which not only secures seams but can also add visual interest.

How to avoid:

- Use overlock or serger stitches to finish raw edges.

- Consider using a French seam for a clean finish, especially on lightweight fabrics.

- Add bias tape to the edges to prevent fraying and add a decorative touch.

Mistake #7:Not Testing with Interfacing or Lining

It is equally important to re-wash these components after manufacturing to prevent shrinkage, which can deform seams and hems. Designers must also consider hand feel, breathability, and stretch of the lining to maintain comfort and ease of wear. Testing on fabric scraps allows compatibility to be evaluated and helps identify adjustments prior to final assembly. For garment manufacturers and traders, this testing phase is critical to maintaining product standards and consistency across collections. Properly selected and tested interfacing and lining enhance the structure, professional finish and wearability of the garment. By thoughtfully integrating these components, designers ensure that the final product performs as intended.

How to avoid:

- Test interfacing and lining materials with fabric scraps to ensure compatibility.

- Select interfacing and lining weight that matches the weight of the fabric.

- Pre-wash interfacing and lining materials to prevent post-construction shrinkage.

Mistake #8: Misjudging Fabric Weight and Drape

Designers must also consider how the pattern and cut interact with the weight of the fabric, ensuring that pleats, gathers, or panels fall gracefully. Choosing the right weight of fabric ensures comfort, aesthetics and longevity of the garment. Neglecting these considerations may require costly adjustments or redesign later. Understanding and respecting the weight and drape of a fabric helps designers create garments that are both functional and visually harmonious.

How to avoid:

- Choose designs that match the characteristics of the fabric.

- Let the fabric’s texture or pattern become the focal point.

- Create prototypes to assess how the design translates with the chosen fabric.

Designing Smarter with Woven Fabrics

Working with woven fabrics requires a careful blend of technical knowledge, creativity and foresight. Every decision from fabric selection and grainline alignment to type of stitching, fit adjustments and finishing techniques can dramatically affect the look, feel and longevity of the final garment. Avoiding common mistakes like ignoring grain lines, misjudging fabric drape, or skipping pre-wash tests ensures that garments remain functional and aesthetically pleasing. Testing, prototyping and evaluating fabric behavior before full-scale manufacturing reduces errors and waste. Continuous learning about different weaves, textures and garment interactions helps designers hone their skills and produce high quality results. By respecting the unique characteristics of woven fabrics and implementing best practices, designers can achieve a balance between innovation and functionality.